M2.5 carbon steel thin head black zinc coating blue patch precision screw

M2.5 carbon steel thin head black zinc coating blue patch precision screw

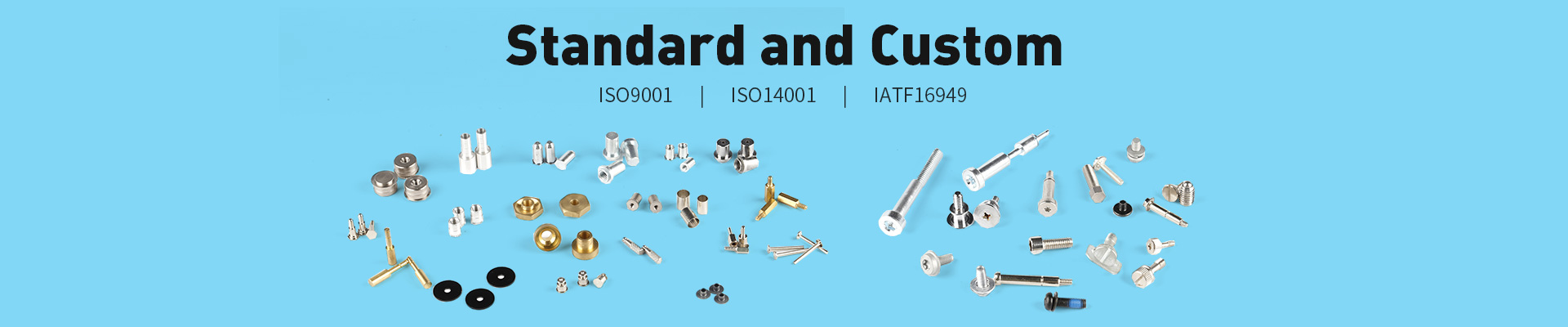

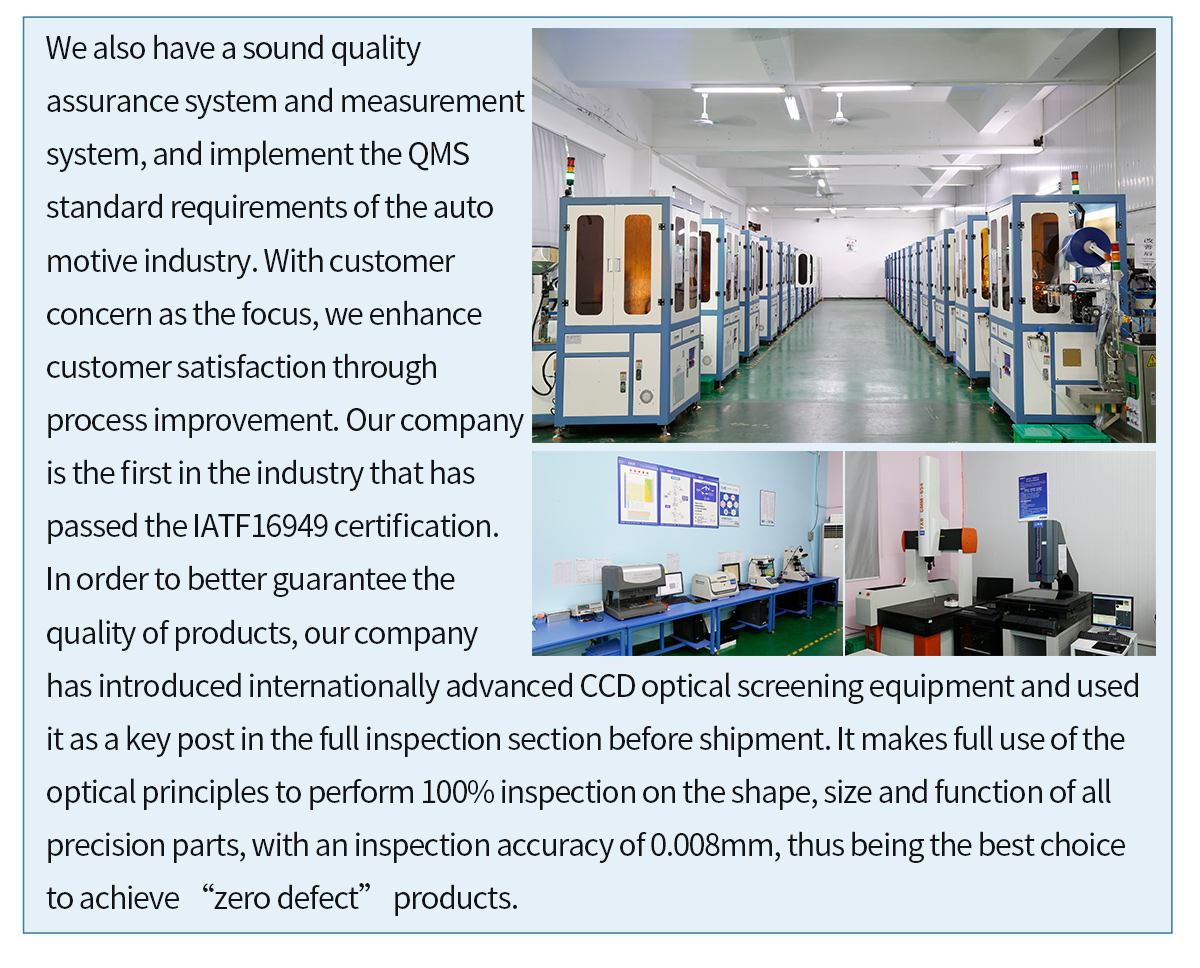

Our organization puts emphasis to the administration, the introduction of talented personnel, and also the construction of team building, making an attempt hard to enhance the standard and liability consciousness of workers members. Our business successfully attained IS9001 Certification and European CE Certification of M2.5 carbon steel thin head black zinc coating blue patch precision screw, Our skilled complex workforce is going to be wholeheartedly at your assistance. We sincerely welcome you to definitely pay a visit to our site and firm and deliver us your inquiry.

Our organization puts emphasis to the administration, the introduction of talented personnel, and also the construction of team building, making an attempt hard to enhance the standard and liability consciousness of workers members. Our business successfully attained IS9001 Certification and European CE Certification of carbon steel black zinc coating screw, m2.5 black screw, We are going to initiate the second phase of our development strategy. Our company regards “reasonable prices, efficient production time and good after-sales service” as our tenet. If you are interested in any of our solutions or would like to discuss a custom order, make sure you feel free to contact us. We have been looking forward to forming successful business relationships with new clients around the world in the near future.

Industry knowledge:

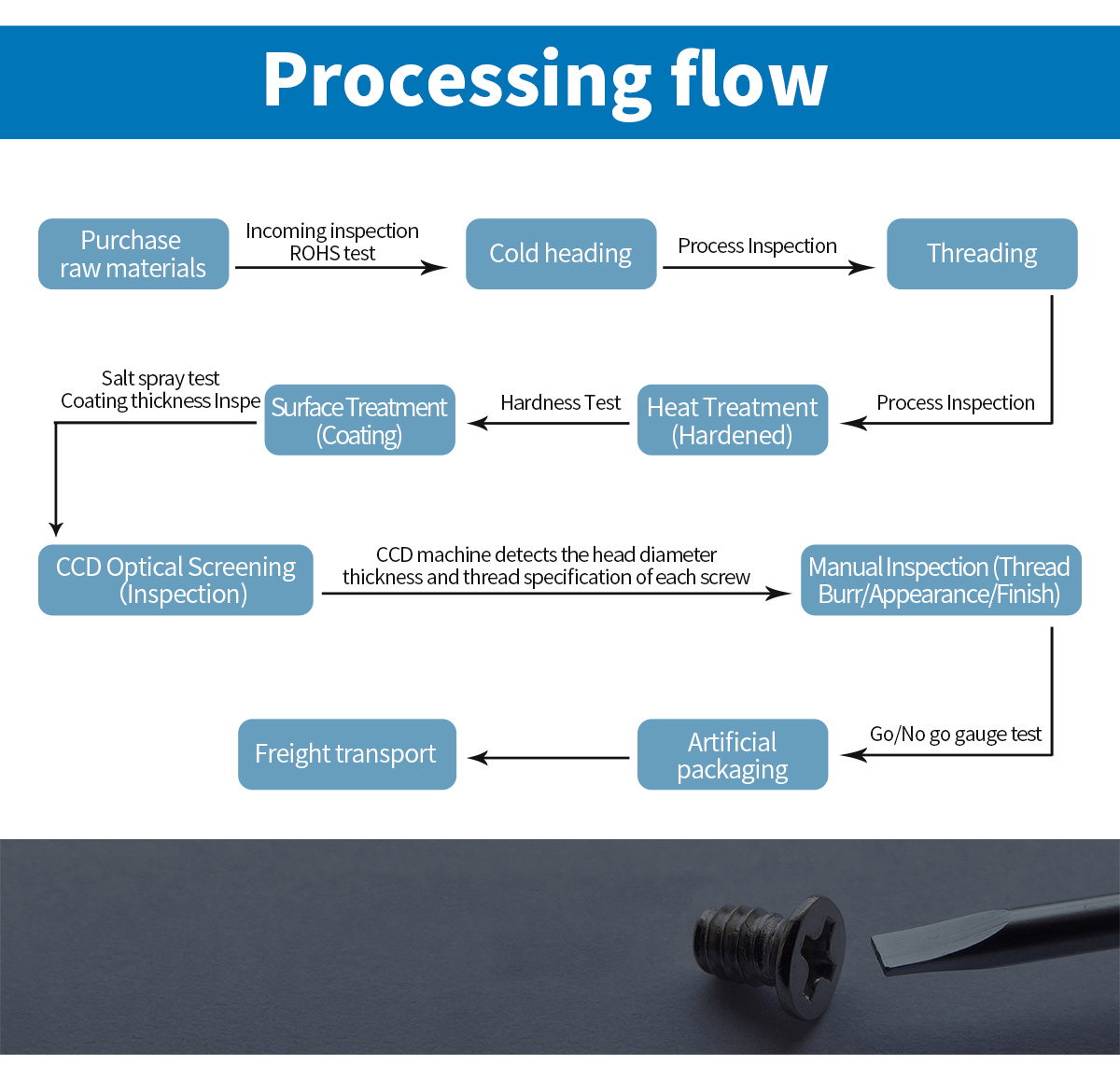

Processing method of screw

1. Turning

The material is made to the desired shape by removing the material

Advantages: high machining accuracy, no mold limit

Shortage: high production cost and slow processing speed

2. Forging

The material is deformed by external force to achieve the desired shape

Advantages: fast production speed, low cost, suitable for mass production

Disadvantages: the forming is limited by the mold, and the mold cost of complex products is high

3. Cold heading: it is a process of extruding and deforming the metal wire with the help of external force in the state of unheated metal wire. The cold heading process is only a kind of forging process.Our organization puts emphasis to the administration, the introduction of talented personnel, and also the construction of team building, making an attempt hard to enhance the standard and liability consciousness of workers members. Our business successfully attained IS9001 Certification and European CE Certification of Manufacturing Companies for China Stainless Steel Flat Head Cross Machine Screws, Our skilled complex workforce is going to be wholeheartedly at your assistance. We sincerely welcome you to definitely pay a visit to our site and firm and deliver us your inquiry.

Manufacturing Companies for China Machine Screw, Countersunk Head Machine Screw, We are going to initiate the second phase of our development strategy. Our company regards “reasonable prices, efficient production time and good after-sales service” as our tenet. If you are interested in any of our solutions or would like to discuss a custom order, make sure you feel free to contact us. We have been looking forward to forming successful business relationships with new clients around the world in the near future.